Lesson

2: Fiber

Optic Tools, Test Equipment and Supplies

Objectives:

From this lesson you should learn:

Tools, test equipment and supplies will be needed to

install fiber optics

Tools needed to learn the skills necessary to install

fiber optics

Guidelines for using and caring for tools and equipment

How to use tools safely

Practice with basic fiber optic tools

Introduction

In order to learn the hands-on skills needed to install

fiber optics, you will need to acquire all the tools, test

equipment and supplies necessary for the hands-on

exercises.

Make certain before you begin that you have everything you

need - tools, test equipment and components. Download

the list of fiber optic technician's tools and

print a copy for your reference. It is a comprehensive

listing and not all may be applicable to the work you do.

Check with each lesson to see what is needed for that

lesson.

NEW:

Purchase inexpensive equipment online and use it for

hands-on lessons. Go

here.

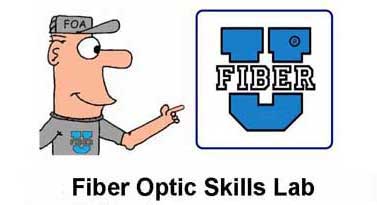

Fiber Optic

Installers’ Tools

Learning the basic skills of fiber optics and the actual

installation of fiber optics requires having the proper

tools and knowing how to use them. These lessons will

give you directions on what tools to use and how to use

them. But first, you need to know what tools are

required and how to take care of them. Here are some of

the tools you use when working with fiber optics.

The 3 popular fiber strippers (from left): Miller,

No-Nik, Microstrip

What Tools Do You Need?

In the Basic Skills Worbook

section on Tools

used in this lesson, you will find a comprehensive list of

tools needed by the typical fiber optic technician who

will install and prep cables, splice and terminate them,

then test the installed cable plant. We also include

typical supplies for termination. We do not include heavy

equipment used for pulling cables.

You can purchase fiber optic tool kits

and/or termination kits that are prepared by manufacturers

for either generic use or to install a particular

component, usually a connector. Connector termination kits

provided by manufacturers are specific for their own

connector type and installation method. Some of these may

be replaced by the more generic tools we list below, but

some connector kits will be required for proprietary

connectors, especially prepolished-splice connector

styles.

Caution

- be wary of cheap prices on brand-name tools. We have

seen counterfeit tools being sold by distributors at low

prices which are useless.

Taking Care of Your Fiber Optic Tools

Nothing is more frustrating that

trying to accomplish something and having problems with

your tools. Whether it is not being able to find a tool or

finding a damaged tool put back in the toolbox without

being repaired or replaced. Read the section

on taking care of your tools in the Workbook

on Tools.

Setting Up A Workspace

We recommend working on a black table mat to make it

easier to see the fiber (and any scraps). It is best

to work on tile or concrete floors, not carpet. If you

drop fiber scraps into carpet they can be very hard to

find or pick up with a vacuum cleaner.

Fusion splicing workspace

Termination with adhesive/polish connector workspace

Clean up after your exercises carefully. Some of the

scrap you generate can be harmful, such as fiber ends,

so we recommend you not work anywhere near food

preparation or children’s play areas! Place clean paper

over your work area to keep from harming the worktable

surface.

Safety

|

Please

Note: This is not the usual online course

- it is intended to guide you as you learn

new skills - the skills needed to install

optical fiber cable plants. It involves

using tools and components in a realistic

manner. Some of the processes here can be

hazardous, like working with sharp scraps

of optical fiber and chemicals. The first

lesson is about safety - we recommend

reading it carefully and posting the

safety rules for everyone to see. Always

wear safety glasses when doing any of

these exercises and dispose of all scraps

properly.

|

In Lesson 1 you

should have familiarized yourself with the safety

procedures - follow them all the time. Do not work with

fiber without safety glasses and a proper work area that

is easy to clean up. It is recommended to not work on

carpeted areas because fiber scraps can become embedded in

the carpet and be difficult to find and remove.

As

part of Lesson 1, you should have watched the FOA

YouTube Video:

FOA Lecture 2: Safety When Working With

Fiber Optics

Download

a FOA safety poster for your work area.

Assignment:

Download the Workbook section,

watch the videos and read the references

before going to the next lesson where these tools will be

used in hands-on activities..

Fiber

U Basic Skills Workbook (Download)

Tools

(PDF, 0.6MB)

List

of Fiber Optic Technicians Tools

FOA YouTube Videos

All FOA

"hands-on" videos and VHO tutorials show the use of

tools, so videos will be referenced in each process

lesson.

Online FOA References:

Fiber

Optic Tools

Book Reference:

NA

Test

Your Comprehension - Online

Quiz On Tools

Have

you completed the Workbook worksheets that are the

records of your having successfully completed the

exercises?

Get a "Certificate

of Completion" When You Complete The Course

After you complete all 6 lessons of the Fiber U Basic Skills Lab

Fiber Optics online self-study course, you can

now take an online exam and, when you pass the

exam, get a "Certificate of Completion" for this

course. You should complete all lessons

including taking the quiz ("Test Your

Comprehension") at the end of every lesson. When

you think you are prepared, you can take an

online exam for a nominal fee ($20) which will

give you a "Certificate of Completion" for

this course.

Take the Test to Get Your

Certificate of Completion For This

Course

- Next: Lesson

3: Fiber Optic Cables

-

Return

to Lesson Plan

|