Completion

Complete each

statement.

|

|

|

1.

|

This is The FOA Online Design Self-Study Program Case Study

No. 6.

An auto manufacturer has many industrial robots in a

manufacturing plant. Each robot is connected to the control room over a duplex fiber optic link using

two fibers. The fiber is chosen for its immunity to electromagnetic interference as the links only

run at 200 kilobits per second. Cables are run to each individual machine and connected to them

inside a small termination box on the side. A conventional patch panel is used in the control

room.

Basic System Information:

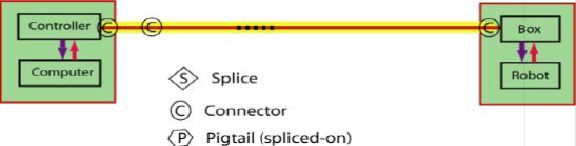

This is the

basic layout of a cable system. Each controller is in a remote control room with equipment connected

to the permanently installed cable plant at a patch panel. A cable is run separately to each robot

and terminated inside a box on the side of the base. The controllers use a relativley low speed

connection with 850 nm LED sources. The system operates over MM fiber or PCS fiber.

Please enter your name, CFOT/Membership number and date to begin this

exercise.

|

Multiple Choice

Identify the

choice that best completes the statement or answers the question.

|

|

|

2.

|

The system runs at low speeds

and has been designed over a decade earlier using both multimode graded-index fiber and PCS fiber.

How does that affect the choice of fiber. Which one

of the following multimode fibers are appropriate for this network?

OM1

OM2

OM3

OM4

a. | Any of these fibers will work | b. | Either OM3 or OM4 | c. | Either OM1 or

OM2 | d. | OM1 only |

|

|

|

3.

|

The backbone cable is run

inside the control room and then outside on the factory floor. The company prefers to not run cable

in conduit, but ruggedness is mandatory. They also prefer to minimize hardware for terminations and

splices. What cable type provides the best protection for fibers in premises

installations?

a. | Zipcord | b. | Distribution | c. | Breakout | d. | Loose

tube |

|

|

|

Typical Specifications

Provided for use as case

studies for design labs in FOA courses.

| Component

Specifications | | | | | Fiber

Loss | | | Multimode

at 850 nm | 3.0 dB/km (TIA 568: 3.5 dB/km) | | Multimode at 1300 nm | 1.0 dB/km (TIA 568: 1.5 dB/km) | | | | | Splice Loss | (TIA 568: 0.3 dB, all

types) | | | | | Connector Loss | (TIA 568: 0.75 dB, all types) | | Multimode, adhesive/polish | 0.3

dB | | Multimode,

prepolish/splice | 0.5 dB | | |

| Active Device and System Specifications | | | | | Digital Transceiver Specs1 | Power (dBm), T=transmit, R=receive | | 850 LED | T: -15 dBm, R: 0 > -25

dBm | | |

Link margin specifications for most

standardized fiber optic networks are on the FOA Tech Topics Site

(http://www.thefoa.org/tech/Linkspec.htm). It should be used as a reference for designers and for the

courses.

|

|

|

4.

|

Using the information supplied above, assuming the component

specifications are per TIA standards, calculate the cable plant loss budget for a 200m link,

including the loss of the patchcords.

a. | 2.95 dB | b. | 1.50

dB | c. | 0.90 dB | d. | 2.11

dB |

|

|

|

5.

|

Using the information supplied above, assuming the component

specifications are typical values and connectors are adhesive/polish types, calculate the cable plant

loss budget for this link.

a. | 2.95 dB | b. | 1.50 | c. | 0.90 | d. | 2.11 |

|

Multiple Response

Identify one

or more choices that best complete the statement or answer the question.

|

|

|

6.

|

What parameters should be tested and documented to confirm

proper installation?

|

|

|

7.

|

Testing of each fiber in the cable should be done as

follows:

(Choose all the correct answers)

|