Lesson

5: Fiber Optic Termination (Connectors)

Objectives:

From this lesson you should learn:

How to identify common fiber optic connectors

How to install connectors using several methods

Adhesive/polish

(epoxy, anaerobic and Hot Melt)

Prepolished/Splice

Singlemode fiber polishing

Prepolished/splice

w/mechanical splice (requires special tools)

Fusion

splice-on connector (SOC) (requires

fusion splicer and accessories)

Tools

And Components Needed

Fiber

stripping tools, crimper, Kevlar scissors, etc. or a

termination toolkit

Polishing plate, pad, puck and film (12, 3 and

0.3-1micron)

Fiber to splice, preferably a simplex cable or half a

zipcord

Download

the list of tools and components needed

or refer to the CFOT

Certification Lab Manual

Introduction

Termination

refers to the process of installing connectors on the ends

of a fiber or fibers in a fiber optic cable. Over the

history of fiber optics, there have been over 100

different types of fiber optic connectors designed using

at least a dozen ways of attaching the connector to the

fiber. Today, factory made connectors use heat-cured epoxy

connectors that are generally polished on a machine. Field

termination may use adhesive/polish techniques with either

heat-cured epoxy, room temperature cured epoxy, anaerobic

adhesives or HotMelt ( a 3M product name) or

prepolished/splice connectors which have a short stub of

fiber inside the connector that are attached with

mechanical or fusion splices.

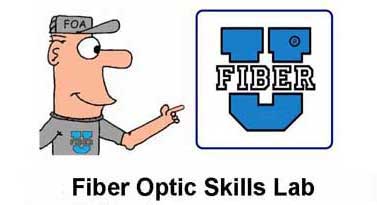

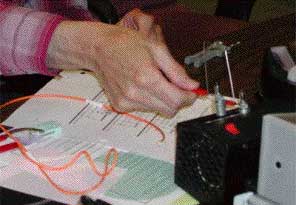

Polishing an

adhesive/polish connector.

The purpose of this lesson is to show you how to install

connectors using the most popular methods. It is

recommended that everyone do at least one of the

adhesive/polish connectors and one prepolished/splice

connector type.

We have provided step-by-step instructions you can follow.

If possible, get instructions from the manufacturer of the

connectors or the tool kit you

are using and follow them as each manufacturer's

connector may have some subtle differences.

Work in a space where you will not be disturbed and avoid

distractions. It is important you concentrate on the

exercises and follow each step carefully.

Allow plenty of time to complete the exercises without

interruption, especially this one on termination. During

the termination exercise, you will use adhesives which

must be used quickly.

Safety

|

Please

Note: This is not the usual online

course - it is intended to guide you as

you learn new skills - the "hands-on"

skills needed to install optical fiber

cable plants. It involves using tools

and components in a realistic manner.

Some of the processes here can be

hazardous, like working with sharp

scraps of optical fiber and chemicals.

In

Lesson 1 you should have familiarized yourself

with the safety procedures - follow them all

the time. Do not work with fiber without eye

protection and a proper work area that is easy

to clean up.

Always wear safety glasses when doing

any of these exercises and dispose of

all scraps properly. |

As

part of Lesson 1, you should have watched the

FOA YouTube Video:

FOA Lecture 2: Safety When

Working With Fiber Optics

Download

a FOA safety poster for your work area.

Background

Review

This "skills" course assumes you

have knowledge of fiber optic

termination. If you are new to fiber

optics, you review the FOA

Guide section on Termination and

Splicing or should complete

the Fiber

U Basic Fiber Optics:

Termination and Splicing

course before attempting the hands-on

exercises here.

Hands-On

Lab Instructions

Download

and read the Workbook termination and the VHO

tutorials on termination for the types of

terminations you will be doing linked below.

Watch the videos and/or read the VHO Tutorials on

the termination types you have available for

practice or are interested in learning. The VHO

"Virtual Hands On" Tutorials take a "step-by-step"

approach to the hands-on processes covered in this

self-study program and the videos will show the

processes in motion. They are both a good way to

teach yourself the processes here - watch the

video for the overview then follow the steps in

the VHO web pages.

*Note: Everyone should study the VHO for

Epoxy/Polish connectors since this is the method

used for patchcords and cables terminated in

factories, representing the lmost common

termination type. The other types can be chosen

depending on personal interest.

Complete the exercises with the equipment you have

available following the steps in the appropriate

VHO Tutorial.

Hands-On

Assignments

After

reading the workbook section and VHO tutorial and

watching the videos, complete these exercises using all

the cable types available to you.

As you finish each section, fill in the worksheet in the

back of the Workbook on Termination. Your completed

worksheets are the records of your having successfully

completed the exercises.

Each of these exercises involves terminating a

tight buffer fiber or simplex fiber optic cable with a

common type of connector.

You should complete the exercises for the all the

components and tools available to you, although it

is recommended that you learn how all these methods

are done to understand the complete process of fiber

optic termination.

Before

starting the hands-on exercises, we recommend you

read these pages in addition to the Workbook

section and the VHO tutorial:

Adhesive/polish

connectors

Hints For Adhesive/Polish Connector Terminations

Arrange all your tools, components and other

items on your work table. Using a black mat (black

Naugahyde works well) makes it easier to see the fiber

when working.

Epoxy and anaerobic adhesive techniques use the same

connector type, the basic ceramic ferrule connector. The

3M HotMelt connector is only made by 3M and will require

the 3M connectors and oven. Prepolished/splice

connectors are available from many manufacturers but

will generally require the termination kit from that

particular manufacturer.

We

recommend starting with either SC or ST connectors with

a 2.5mm ferrule as they are somewhat easier to terminate

than the smaller 1.25mm ferrule of the LC. After

mastering the techniques, try the LC connectors with

smaller ferrules.

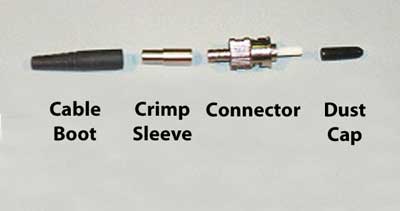

Parts of an ST

connector

Hint: Since it is preferred to be able to test

each connector as it is made, we recommend starting with

a long patchcord, say 5 meters long, then cut it in half

and attach your connector to the cut end. That allows

testing your connector as soon as it is made using the single-ended

(patchcord) test. Record all test data on your

connectors.

Adhesive/Polish

Connectors

Adhesive/polish connectors all have a

similar process (from left): strip the fiber to the

proper length, apply adhesive and insert the connector,

after the adhesive sets, cleave the fiber, air-polish to

remove most of the fiber stub, final polish on a flat

plate with a soft polishing pad.

Fill

in the worksheets at the end of the Workbook section

on Termination as you complete the tasks.

1. Epoxy/polish Connectors

Read: Adhesive/polish

connectors

- VHO:

Epoxy/Polish

Follow

the directions to terminate a fiber or simplex cable. The

8-part videos above give detailed instructions.

The VHO:

Epoxy/Polish web pages show step-by-step

instructions that are easy to follow.

Epoxy must be injected

into the connector with a syringe.

Inject adhesive until it forms a small bead on the

connector ferrule. When this bead hardens, it supports and

protects the fiber during polishing to allow a better end

finish. This hardened bead of epoxy means the yield of

epoxy/polish connectors is nearly 100%. Thus epoxy/polish

connectors have the highest yield, best reliability and

lowest loss of any termination type.

Inject epoxy until you

see a small bead of the adhesive on the end of the

ferrule.

Many novices think

epoxy connectors take too much time - it does take 5-10

minutes to cure epoxy in an oven. But if you are

terminating more than one connector, the first connector

goes into the oven and will be ready by the time the

second or third connector goes in the oven, so the curing

time is irrelevant.

Epoxy

usually only has a 30 minute life once mixed. If you are

working with others, you can share the epoxy to be more

efficient.

If you have a curing oven, the epoxy will cure in 5-10

minutes. Room-temperature curing epoxy will need to be

left overnight.

2.

Anaerobic /polish Connectors

Read:

Adhesive/polish

connectors

VHO:

Anaerobic

Several

methods are used for applying an adhesive and some use

an “accelerator” or chemical thatmakes the adhesive

set instantaneously. These methods are:

- Inject

adhesive into the connector and dip the prepared fiber

end into the acceleratorbefore inserting it in the

connector. One must work quickly as the adhesive sets

in 30 seconds or so, so if trouble getting the fiber

intothe connector is encountered, the adhesive may set

before the fiber is fully inserted.

- Inject

adhesive into the connector and then insert the

prepared fiber end into the connector. Spray or drop

theaccelerator on the protruding fiber and move the

fiber back and forth to spread the accelerator inside

the connector ferrule. It should set in ~30 seconds.

- Wipe

the fiber with the adhesive and insert it in the

connector. With noaccelerator, the adhesive will set

in 4-5 minutes and be much stronger. If instant

adhesion is required, spray or wipe accelerator on

theprotruding fiber as above.

The original method developed decades ago was to inject

the adhesive in the connector then dip the prepared

fiber in the accelerator and insert it. The problem with

this method was the adhesive would set so fast that

often one could not get the fiber fully inserted in the

connector before the adhesive hardened, requiring the

connector to be discarded. Try this method also to see

if it works for you.

When cleaning fibers for anaerobic connectors (or any

connector for that matter), NEVER use regular medical

alcohol or alcohol pads. The 30% water content makes the

adhesive take much longer to cure (if it ever cures) and

makes the bond to the connector ferrule less strong.

-

-

3. 3M HotMelt

Connectors:

Read:

Adhesive/polish

connectors

VHO: Hot

Melt

Follow the directions to terminate a fiber or

simplex cable. The VHO gives detailed

instructions.

VHO:

Hot

Melt

HotMelt

connectors use an adhesive that is applied to the

connector at the factory and is then heated up to

liquify it to allow insertion of the stripped and

cleaned fiber. The connector is then set aside to cool

and set for several minutes before the fiber can be

polished.

For this exercise, you will need a special 3M Hotmelt

oven. HotMelt ovens use a much higher temperature than

epoxy overs, so they are not used for any other purpose

- the high temperature will ruin epoxy.

Inserting a HotMelt

connector in a 3M oven

One advantage of the HotMelt connector is you may be

able to reuse them. If you break the fiber or have

problems in the cleaving or polishing process, you can

heat the connector up and remove the fiber and try

again. Or you can strip the fiber ~3mm (1/8") longer and

after inserting it fully, pull it back 3mm and let it

set. If you have problems with cleaving

or polishing, reheat the connector, push the fiber

fully in, let it cool and try again.

4.

Prepolished/Splice Connectors

- Read:

Prepolished/splice

connectors

- VHO:

Pre-Polished

Splice& SOC

Hands-on

lab with step-by-step directions

Follow

the directions to terminate a fiber or

simplex cable. The VHO gives detailed

instructions. VHO:

PPS

Termination

Prepolished/splice connectors are connectors with a

short fiber stub already installed in the connector

and polished, allowing the connector to be installed

on a fiber using a splice. The splice has

traditionally been a mechanical splice but fusion

splices are now available for use with some

connectors, sometimes requiring special splicing

machines, sometimes regular fiber splicers.

Each manufacturer's prepolished/splice connector is

slightly different. It is important to follow their

instructions exactly to get good results.

The most important issue with any prepolished/splice

connector is to ensure the fiber is cleaved

properly. Many kits for these connectors provides

only a simple, cheap cleaver that looks like a

stapler. If used properly, these cleavers can

provide adequate cleaves, but they require practice

and a technique that not every tech can master. More

expensive cleavers such as those used for fusion

splicing are recommended to prevent problems.

Remember that a poor cleave will not only cause high

loss, it usually causes the need to cut off and

discard an expensive connector.

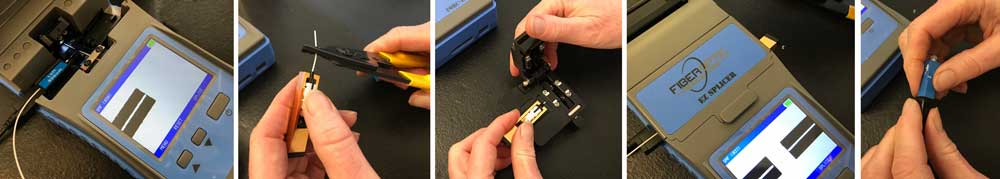

5.

Fusion Splice-On Connectors (SOC)

- Read:

Prepolished/splice

connectors

- VHO:

Pre-Polished

Splice& SOC, Detailed

sequential instructions on installing a SOC using

the EasySplicer

(shown above.)

The SOC is a

prepolished connector made in a factory with a short

length of cleaved fiber that is fusion spliced onto the

fiber being terminated. The SOC process is

straightforward, much like fusion splicing. Strip the

fiber, cleave it with a fusion splice cleaver, place the

connector in the fixture in the splicer, fuse the fibers,

shrink a protector over the splice and place the boot on

the connector.

Each

manufacturer's SOC is slightly different. It is important

to follow their instructions exactly to get good

results.

6.

Singlemode Polishing: Follow

the directions to terminate a

fiber or simplex cable. The VHO

gives detailed instructions.

Read:

Singlemode

fiber termination

VHO: Singlemode

Not

many techs attempt field installation of singlemode

connectors using adhesive/polish techniques. It is very

hard to get low loss and especially reflectance with

hand-polished SM connectors so most are factory

terminated on a pigtail which is fusion spliced onto the

fiber in the field. Furthermore, most SM connectors are

tested with an interferometer to verify the quality of

the end finish. However we offer instructions to those

who want to learn how to polish SM connectors.

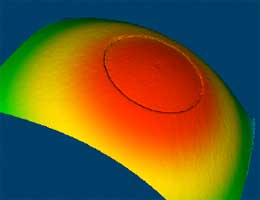

Interferometer test of a

SM connector

If

you do not have access to an interferometer but want to

know how good your connectors are, use a reflectance test

to check them. Read: Reflectance

Testing

Have

you completed the Workbook worksheets that are the

records of your having successfully completed the

exercises?

Test

Your Comprehension - Online

Quiz On Termination

- Next: Lesson

6: Fiber Optic Testing

Get a "Certificate

of Completion" When You Complete The Course

After you complete complete all six lessons of the Fiber U Basic Skills Lab

Fiber Optics online self-study course, you can

now take an online exam and, when you pass the

exam, get a "Certificate of Completion" for this

course. You should complete all lessons

including taking the quiz ("Test Your

Comprehension") at the end of every lesson. When

you think you are prepared, you can take an

online exam for a nominal fee ($20) which will

give you a "Certificate of Completion" for

this course.

Take the Test to Get Your

Certificate of Completion For This

Course

Return

to Lesson Plan

|